Heat Exchanger Tube Replacement

Enerbay specializes in the custom design, engineering and fabrication of process equipment for Chemical Processing and related industries.

We are dedicated to meeting your business needs by offering design and fabrication capabilities in a wide range of pressure vessels and heat exchangers. Our expertise includes storage tanks, mix tanks and other process vessels .In heat exchangers we concentrate on the shell and tube type, fixed tube sheet units and u-tube units.

Enerbay Exchanger works to our customer’s equipment requirements in both solid and clad stainless steel and nickel alloy .With an exceptional technical staff, our engineering and design combines experience, ingenuity and flexibility with the latest in computer-assisted design capabilities. we are active in new fabrication plus the repair and modification of existing pressure vessels and heat exchangers.

Our Services and expertise can essentially be utilized in the following areas:

- Oil Refineries

- Petrochemical Plants

- Fertilizer firms

- Power Plants

- Desalination plants etc.

- Petrochemical Plants

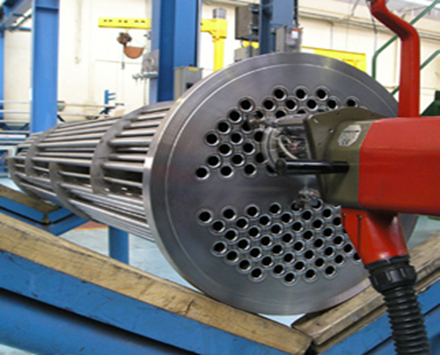

- Re-tubing

Genuinely we focus on the pressure vessels; especially heat exchangers, condensers, evaporators and boilers and fin fan coolers. Initially our main mode of operation will be the re-tubing of heat exchangers and condensers of any size and volume.

Careful re-tubing assisted by sophisticated machinery and efficient manpower facilitates to salvage the baffle plates, tube sheets and related attachments ,thus saves the cost on the refurbishment of any afore named

So Far we achieved a bright opportunity to carry out a few challenging jobs related to evaporators for desalination plants. Those were of higher volumes ranging up to 65000 tubes, could achieve the targets well before the stipulated timing meeting all the stringent standards, thus the acceptance of the accredited TPI’s.

Tubing Jobs:

- Trimming

- Tube to tube sheet expansion

Reasons for puncture and corrosion in tubes:

Even though high quality materials are used, the following reasons cause the damage of tubes.

- Thermal expansion of tubes – Difference in temperature through the width of tubes

- Stress from high pressure & corrosive character of the fluid

- Vibration & Erosion – The fluid passes through the tubes causes vibration against the baffle plates culminates into erosion. Ultimately leaking will result in fluid cross-contamination thus evolves the loss of pressure

IMPORTANCE OF RE-TUBING

1. Leakages thro tube and tube to tube sheet joints in heat exchangers in Fertilizer, Refineries and Petrochemical plants particularly in corrosive service are serious cause of concern for Reliability of static equipment. Unlike rotary equipment it is not common to have spare heat exchangers and hence Heat Exchangers are normally classified as Single Line equipment whose down time can lead to serious production losses

2. Heat exchangers are normally over designed & leaking tubes can be plugged to the extent of 10 % normally .Any loss of tubes beyond this limit needs major repair/replacement.

3. It is common to keep spare tube bundle (only for floating head exchangers) particularly in corrosive service but for fixed exchangers, keeping spare exchangers is not an economic option, where insitu-re-tubing on fast mode is the best choice during short term or long term shutdown.

4. In such cases Re-tubing becomes an optimum solution. Since the cost of other major components like shell, channel cover, dome, tube sheet etc (which normally do not need replacement) is substantial (40-60%) when compared to tubes, it is prudent to change tubes only rather than replacing the whole heat exchanger.

5. Since such Re-tubing can be done only during equipment outage, it is imperative that it is done in shortest possible time to keep the production losses as minimum.

6. Re-tubing accordingly has become an highly technical & skilled area now which needs many special tools, tackles, test methods. The procedure requires special skills & training and is passing through continual improvement process with inputs from industry & Re-tubing contractors.