Power Plants

Natural Gas Power Plants:

Enerbay, with its JV partners, offers a whole process of building power from the civil engineering and construction work all the way through to final commissioning of the plant. We can provide expertise and personnel to operate the plant. We also offer to build the plant on BOT system.

Natural gas is a cleaner and more efficient source of electricity compared to coal and oil. When combined with the world’s abundant supply, it is an essential fuel in meeting our future demands for power generation.

The future of Power plants is rapidly shifting from coal to natural gas every year. The benefits of switching to natural gas power generation include:

- Substantial Reduction of carbon dioxide emissions up to 60%.

- Large amount of reduction in other harmful pollutants normally associated with coal

- Elimination of mercury emissions,

- Less natural gas to produce one kilowatt-hour of electricity.

Coal Power Plants

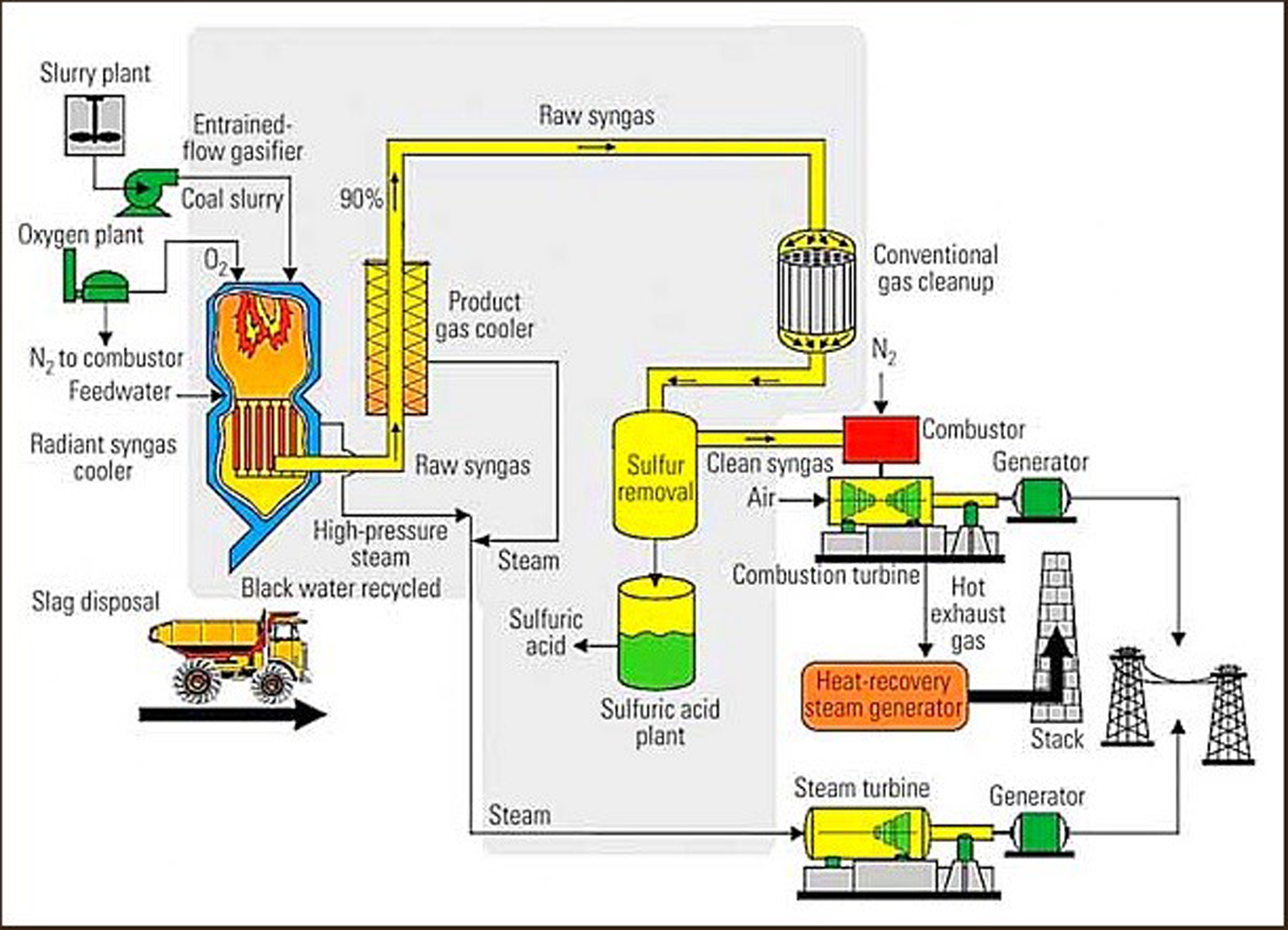

Enerbay uses state-of-the-art electric power plant technology. We can implement traditional coal fired as well as advanced coal gasification power plant. In our advanced coal gasification technology, emission control is simpler in gasification than in combustion because the produced syngas in gasification is at higher temperature and pressure than the exhaust gases produced in combustion. Such high temperatures and pressures allow for easier removal of sulfur and nitrous oxides (SOX, and NOX) and other heavy metal trace contaminants. Similar to the removal of other contaminants, gasification lends itself to efficient carbon dioxide (CO2) removal because of the high temperature and pressure of the produced syngas. The energy produced is much cleaner and highly efficient.

Gasification can be coupled with advanced turbine technology to produce electricity efficiently. Syngas produced by gasification can also be further processed into liquid fuels (diesel, gasoline, jet fuel, etc.), hydrogen and synthetic natural gas, or a range of fertilizers or other high-value chemicals including anhydrous ammonia, ammonium sulfate, sulfur, phenol, naphtha and, among many others. In addition, slag produced from coal ash can be used in the production of building materials such as asphalt and cement.

Electricity generated from IGCC has fewer emissions than existing pulverized coal power plants.

Combined-Cycle Power Plant for Electricity Production

A combined-cycle power plant uses both a gas and a steam turbine together to produce up to 50 percent more electricity from the same fuel than a traditional simple-cycle plant. The waste heat from the gas turbine is routed to the nearby steam turbine, which generates extra power.

This is how a combined-cycle plant works to produce electricity and captures waste heat from the gas turbine to increase efficiency and electrical output.

- Gas turbine burns fuel.

- The gas turbine compresses air and mixes it with fuel that is heated to a very high temperature. The hot air-fuel mixture moves through the gas turbine blades, making them spin.

- The fast-spinning turbine drives a generator that converts a portion of the spinning energy into electricity.

- Heat recovery system captures exhaust.

- A Heat Recovery Steam Generator (HRSG) captures exhaust heat from the gas turbine that would otherwise escape through the exhaust stack.

- The HRSG creates steam from the gas turbine exhaust heat and delivers it to the steam turbine.

- Steam turbine delivers additional electricity.

- The steam turbine sends its energy to the generator drive shaft, where it is converted into additional electricity.

Main Advantages of Combined Cycle

- Mainly the efficiency of the combined cycle plant is better or higher than the turbine cycle or steam cycle plant. The efficiency of combined cycle power plant will be of the order of about 45 to 50%.

- The combined cycle power plant is more suitable for rapid start and shutdown than the steam power plant. Therefore this plant accepts load variations quickly and helps in maintaining the stability in the electrical grid.

- The cooling water requirement of the combined cycle plant is much lower than the normal steam turbine power plant having same capacity output. In these type of plants almost 2/3rdof the power is generated by the gas turbine plant which requires very little or no cooling water. Conventional cooling water system (once through) or recycle system is adopted. In case of lack of sufficient water at the site, dry cooling system can also be provided for cooling. Less water requirement for combine cycle plants is also major advantage while selecting the site of the plant.

- The combined system offers self-sustained feature. For example if the plant is shut down due to any fault or maintenance, no start up power supply can be required to start the unit. Gas turbine offers to start the plant and supply power to plant auxiliary loads. Therefore combined cycle plants have advantage of self sustaining feature.

- Combined cycle plants have the advantage of high ratio of power output to the area occupied. Therefore for designing a combined cycle plant space requirement is not a concern

- It has the advantage of low operational personnel.